Embrace the Future: AI-driven Asset Management for Business Efficiency and Growth

.18.04.2023

As technology evolves, businesses across industries are turning to AI-driven asset management to optimize their operations and maintain a competitive edge. For instance, the largest electrical utilities company in Portugal, headquartered in Lisbon, has adopted an AI-enabled solution for automating utilities inspection through image gathering and data annotation. This innovative approach not only streamlines the inspection process but also paves the way for proactive maintenance and cost optimization.

Implementing AI-driven asset management can help businesses improve efficiency, reduce costs, and make informed decisions about resource allocation. By harnessing the power of AI, companies can proactively identify areas of improvement, transforming their approach to maintenance and overall asset management.

The customer

Our client is EDP, the largest Portugal electrical utilities company headquartered in Lisbon.

The context

Keeping a nation’s lights on means constantly inspecting electricity poles for damage. However, for our client, this meant flying teams of specialists with helicopters to survey and photograph electricity poles in midair and manually fill out damage reports. It was a slow, labor-intensive, and expensive way of finding out which poles needed fixing. To assist our client, we created an AI-enabled detection model that would make the process a lot simpler and cost-effective.

The solution

Step 1 – Pole detection

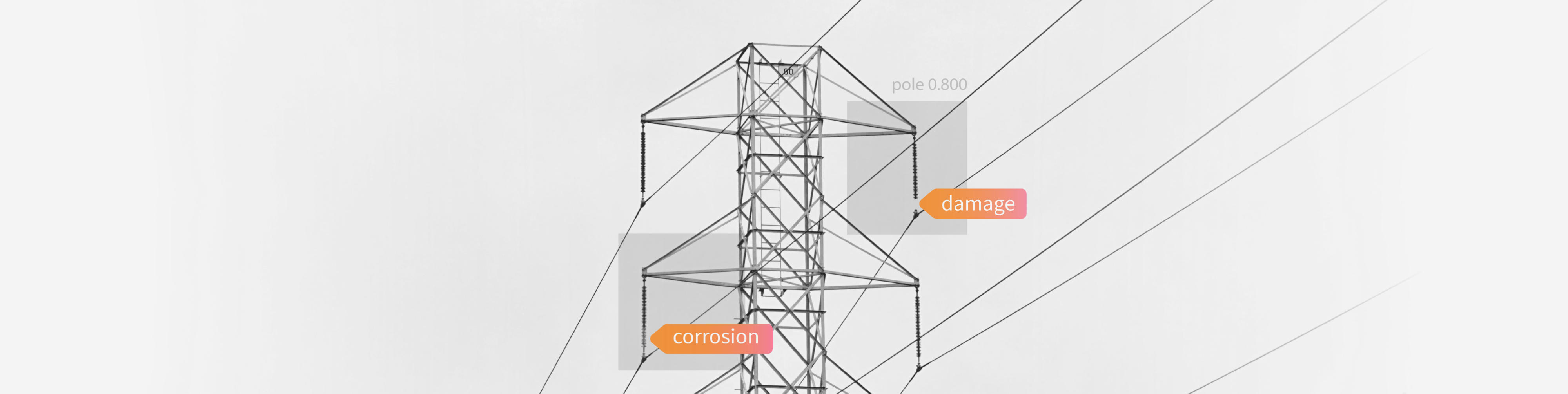

As a proof-of-concept, we first delivered a model capable of identifying electricity poles and their components, like insulators and crossbars. That meant gathering 12,500 images — 7,000 with poles —then annotated by our highly-skilled 500,000+ strong crowd. We used 3,000 of those images to train a pole detection model and 500 more to test it.

Step 2 – Damage detection

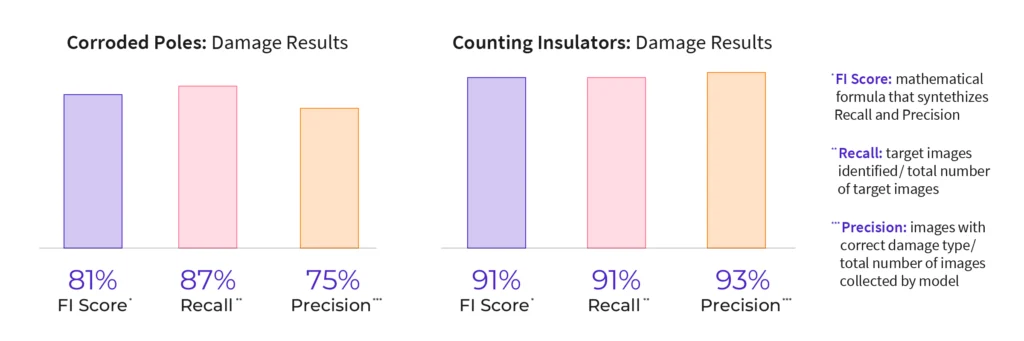

Next, we built damage detection models by hand-selecting a subset of 900 high-resolution images to send to our crowd, who identified the type of damage in each image. We used those annotated images to train and test one model to keep track of damaged or missing insulators and another to detect corrosion on crossbars.

Harnessing AI for Proactive and Cost-effective Asset Management Solutions

With these models, our client is on the path to faster, cheaper, and more accurate asset management processes (APM). In the short term, that means drones will feed high-quality images of poles into automated systems that will deliver comprehensive damage reports as a result. In the long term, automated APM will allow our client to ask and answer more sophisticated maintenance questions. Put simply, instead of reacting to already damaged poles, the automated ADM will allow our client to proactively identify which poles will need fixing in the future.

Are you ready to revolutionize your business with AI-driven asset management? Get in touch with us today to learn how our cutting-edge solutions can help you optimize operations and drive growth.